After 50 years of lag, automakers realize turbochargers

In the course of nearly 100 years of automobile development, the most widely accepted concept to increase vehicle horsepower is to manufacture large engines. As many car enthusiasts know, stricter fuel economy standards and vehicle miniaturization require 21st century automakers to find equal or greater horsepower in small engines. Turbochargers convert underutilized exhaust gas into improved engine efficiency and have entered the General Motors market from high-performance cars.

Ford Motor Company’s popular EcoBoost engine, the TDI powerplant produced for Volkswagen and Audi vehicles, as well as the most popular Porsche performers, are members of the modern turbocharger revolution. In the recent update of the BMW M5, the German auto company downsized their V-10 engine in favour of a twin-turbocharged V-8 powerplant. The result for the

2012 BMW M5

was more than 560 horsepower (60 horsepower extra than the previous engine) but capable of running roughly 4 miles further per gallon in average driving. As the turbocharged engined 2012 model year vehicles are being sold with great enthusiasm, the

forced air induction technology

marks a 50-year trip since entering into production automobiles.

When pondering the first auto manufacturer to install a factory turbocharger, today’s assumptions would make us believe a Japanese or European company that found promise in the engine component. In fact, the first major factory application of a turbocharger on a gasoline engine was found on the American-made Oldsmobile F-85 Jetfire and Chevrolet Corvair in 1962.

Called the Turbo Rocket powerplant, the aluminum V-8 produced an additional 60 horsepower over the conventional 215 cubic inch (3.5 liters) engine. Producing 215 horsepower, the Oldsmobile F-85 Jetfire became a late member of the ‘one horsepower per cubic inch’ fraternity in the American auto industry. Unusual for the era, the early exercise with turbochargers saw Oldsmobile engineers add a rather unorthodox cylinder treatment procedure. Added to the air/fuel mixture, distilled water, and methyl alcohol was injected into the 215 cubic-inch turbocharged engine’s combustion chambers to help maintain a proper operating temperature. Debuting in mid-1962, the Oldsmobile F-85 Jetfire with the turbocharged engine would only last through 1963; over 8,500 examples were created.

General Motors also tried turbochargers on non-eight cylinder engines by adding the units to the Chevrolet Corvair. Debuting 1962 on the Corvair Monza model, the engine produced 150 horsepower. Ford 1965 and 1966, an improved turbocharged version of the embattled rear-engined Chevrolet Corvair, was made available with the flat-6 powerplant. Obtaining 180 horsepower from a 164 cubic inch engine, the efforts to promote turbochargers in smaller vehicles were defeated by the bad publicity brought against Corvair.

As the muscle car era had American automobile buyers craving big V-8 engines, General Motors declared an unofficial moratorium on turbocharger units. Even as the oil crisis caused auto manufacturers to think of downsized vehicles in the late 1970s, the technical advantage of turbochargers was rarely brought to production. During the same time, the world has become wise to turbocharging, with Porsche and BMW selling their first models using the forced-air induction system. Mercedes-Benz and Peugeot also made the first turbodiesel passenger cars available to the European public in the late 1970s.

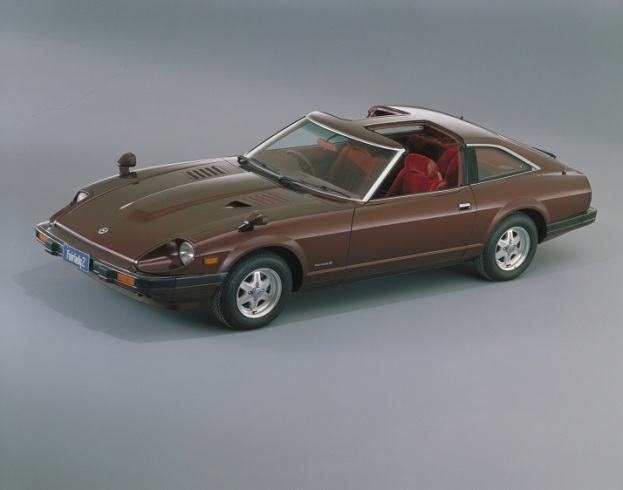

By the start of the 1980s, Japanese auto companies realized turbocharging as a way to pick up power from their smaller engines. The Toyota Supra, Mitsubishi Lancer, and Nissan 280ZX stormed the North American market as performance driving entered an era of higher fuel prices. Coinciding with the widespread adaptation of fuel injection, turbochargers came a new statement for high technology in automobiles. Rushing back into the turbocharger game, American auto companies adopted turbocharged engines as a performance enhancement around the horsepower lost to choking emission control hardware. Added to the Pontiac Firebird and the Chrysler K-Cars, Buick made a name for itself with a special version of the two-door Regal. In 1987, the Buick GNX powered by a turbocharged, 231 cubic-inch V-6 was recognized as the fastest accelerating production car built in the United States.

Through the 1980s and 1990s, the turbocharger became more noted for reaching the plateaus of high-performance. Limited to cost as well as the increased complexity, turbocharger units were also held back by a mechanical performance delay called turbo lag. Eventually, auto engineers discovered the use of twin turbochargers could overcome the compromise of where optimal turbo power would be delivered. The most recent development was the variable geometry turbocharger that adjusts the profile of the impeller for any speed.

With technology evolved and perfected, turbochargers have struck the mainstream market on new vehicles such as the

Chevrolet Cruze, Kia Optima as well as Ford F-150 pickup. 50 years since General Motors installed the forced-air unit on a showroom-destined vehicle, and the turbocharger is potentially the best-known way to help obtain fuel efficiency while pleasing are need for performance motoring.

Information source: hot cars in the 1960s, Nissan Americas, Porsche AG. Image source: Chris Nagy, Nissan Americas

-

Latest

Overview of Kia Carnival 2022: This next-generation minivan is ready to rumble!

Overview of Kia Carnival 2022: This next-generation minivan is ready to rumble!The Kia Carnival in 2022, formerly known as Sedona, is the first Kia car in the United States to carry the brand’s eye-catching new logo. The 2022 Carnival is also the most eye-catching minivan we hav...

-

Next

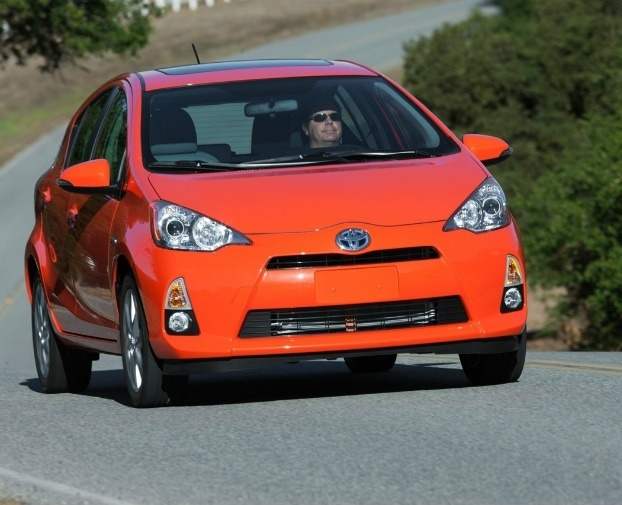

2012 Toyota Prius C 4 Review

2012 Toyota Prius C 4 ReviewThe 2012 Toyota Prius c just launched this spring is a brand new model, and the "c" represents the city. In the case of 53 mpg, Prius c should be an ideal city car because it offers the highest city m...